Le savoir-faire de BRC réside dans sa capacité à créer des caissons sur-mesure et trouver des solutions pratiques pour protéger le matériel et équipements sensibles de ses clients (militaires ou civils).

En effet les caissons rotomoulés existants sur le marché nécessitent souvent qu'il faille s'adapter au caisson (taille, volume, usinage fastidieux, non CEM...).

La solution de SUR-MESURE de BRC permet exactement l'inverse, c'est à dire que c'est le caisson qui s'adapte au matériel ou aux spécifications propres du client.

En terme de coût, le Sur-Mesure est souvent moins cher et directement opérationnel pour le client.

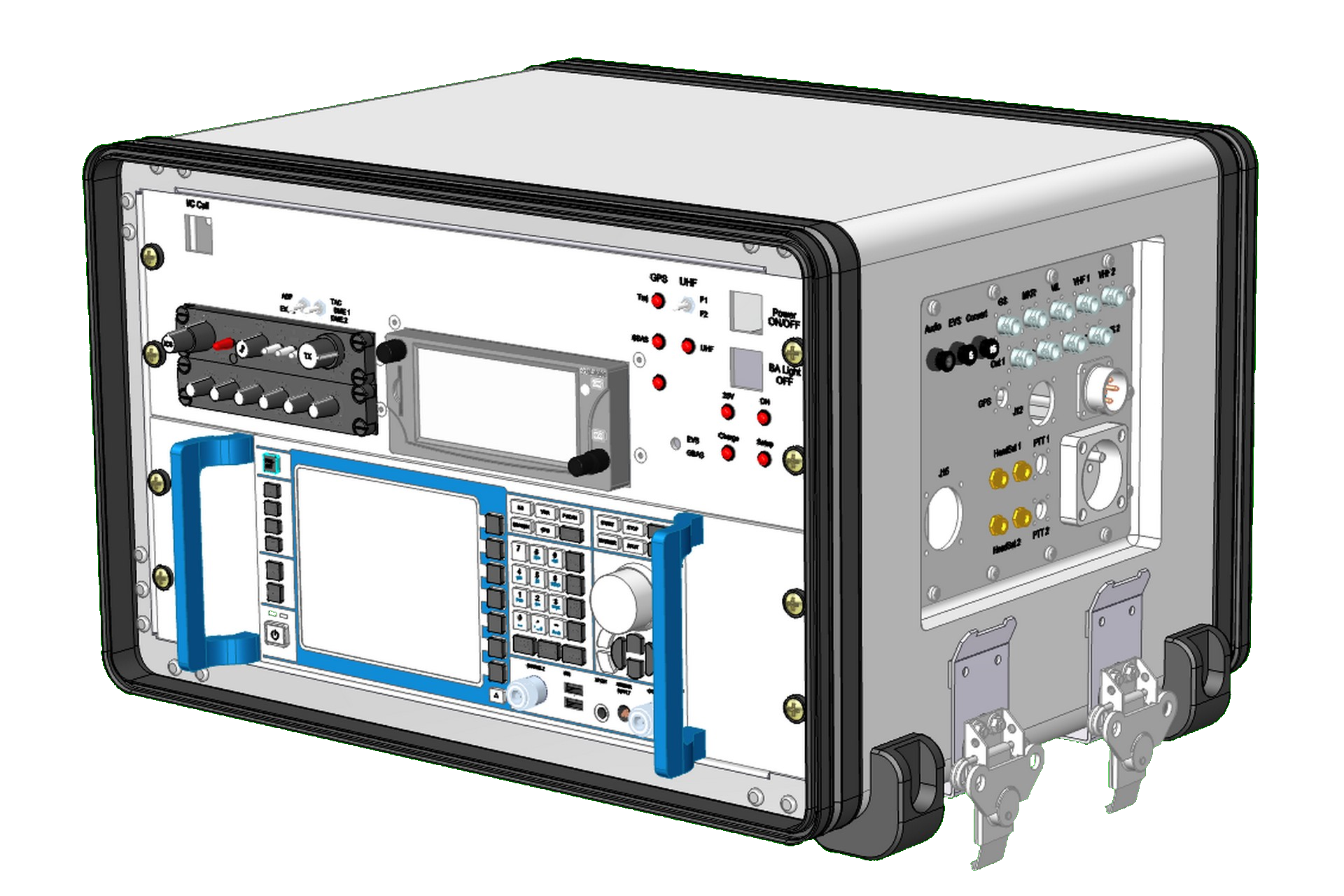

Les caissons sécurisent le stockage, le transport, la mise en opération du matériel, ou facilitent l'utilisation du matériel et des équipements sur le terrain.

Les agressions et contraintes habituelles sont mécaniques (chutes, chocs, vibration), climatiques (étanchéité, T°, brouillard salins, décompression,...) ou CEM.

Les aspects incendies et fumées toxiques sont gérés par l'utilisation de résine M1F0 ou M1F1.

La protection des personnes avec des caissons 14S est un aspect maitrisé par BRC.

PROTÉGER avec des solutions SIMPLES ET EFFICACES, des caissons légers sans jamais compromettre la résistance.

Dès la réception de la STB (Spécification Technique du Besoin), le bureau d’études réalise :

- Des études de faisabilité

- Des plans 3D intégrant les solutions adaptées aux contraintes

- Les matrices de conformité pour contrôler l'adéquation aux besoins

- Les prototypes produits

- Les essais utiles pour valider les choix proposés

Notre bureau d’études travaille en étroite collaboration avec les plateaux projets clients pour optimiser en permanence les dimensions, poids, ergonomie et coûts des caissons.

Dès la phase de conception, nous intégrons la nécessité de devoir produire les caissons sur le long terme... [En savoir +]

Dès la réception de la STB (Spécification Technique du Besoin), le bureau d’études réalise :

- Des études de faisabilité

- Des plans 3D intégrant les solutions adaptées aux contraintes

- Les matrices de conformité pour contrôler l'adéquation aux besoins

- Les prototypes produits

- Les essais utiles pour valider les choix proposés

Notre bureau d’études travaille en étroite collaboration avec les plateaux projets clients pour optimiser en permanence les dimensions, poids, ergonomie et coûts des caissons.

Dès la phase de conception, nous intégrons la nécessité de devoir produire les caissons sur le long terme (5 à 25 ans). La maitrise en interne de tous les processus de fabrication permet d’être en permanence réactif et efficace

La très grande diversité des projets réalisés nous permet d'être en permanence force de proposition et d’innovation.

BRC créée des produits sur mesure à partir de son savoir faire unique et de ses standards propres pour répondre au mieux aux attentes de ses clients.

Les clients de BRC sont essentiellement les grands industriels français du monde civil ou militaire, mais aussi les RH de la sécurité intérieure française. Chaque projet a des contraintes différentes :

- Caisson pour protéger un système Lidar localisé sur des bouées en Haute Mer

- Caisson pour protéger une baie de 42" entièrement intégrée lors de son transport aérien

- Caisson Range pour transporter et manutentionner en sécurité des grenades pour les interventions en milieu dégradé

- Caisson VIB avec ou sans climatisation pour permettre le déploiement SATCOM en extérieur

- Caissons sécurisés pour transporter le courrier diplomatique

- Caisson en aluminium climatisé ou avec échangeur thermique pour réguler les températures

- Caisson avec des vannes spécifiques pour faire face à une décompression rapide en avion.

... [En savoir +]Les clients de BRC sont essentiellement les grands industriels français du monde civil ou militaire, mais aussi les RH de la sécurité intérieure française. Chaque projet a des contraintes différentes :

- Caisson pour protéger un système Lidar localisé sur des bouées en Haute Mer

- Caisson pour protéger une baie de 42" entièrement intégrée lors de son transport aérien

- Caisson Range pour transporter et manutentionner en sécurité des grenades pour les interventions en milieu dégradé

- Caisson VIB avec ou sans climatisation pour permettre le déploiement SATCOM en extérieur

- Caissons sécurisés pour transporter le courrier diplomatique

- Caisson en aluminium climatisé ou avec échangeur thermique pour réguler les températures

- Caisson avec des vannes spécifiques pour faire face à une décompression rapide en avion.

- Valises "blindées" pour protéger les équipements des ondes extérieures

Pour toutes ces applications BRC, réalise des matrices de conformités et procède auprès de laboratoires extérieurs les qualifications nécessaires.

Lorsque nécessaire, BRC manage les opérations d'intégration et de câblage du matèriel client auprès de son réseau de partenaires spécialistes en la matière.

BRC recherche en permanence des solutions innovantes pour répondre aux attentes clients :

De nombreuses solutions développées par BRC et que vous ne trouverez pas sur le marché :

- Des systèmes de climatisation ou d’échangeur Air / Air

- Un système de QR code intégré

- Un surmoulage des logos clients

- Des housses de protection lors des opérations d’intégration de votre matériel

- Des solutions de gerbabilité pour des caissons BRC ou non-BRC

- ....

ET surtout en 2021 le dépôt des marques Xtra-Lucem et Lucem-Light qui caractérisent le développement de nouveau composite plus léger (-50% vs des composites ou pièces en aluminium classiques) et plus résistant (+30%)

BRC recherche en permanence des solutions innovantes pour répondre aux attentes clients :

De nombreuses solutions développées par BRC et que vous ne trouverez pas sur le marché :

- Des systèmes de climatisation ou d’échangeur Air / Air

- Un système de QR code intégré

- Un surmoulage des logos clients

- Des housses de protection lors des opérations d’intégration de votre matériel

- Des solutions de gerbabilité pour des caissons BRC ou non-BRC

- ....

ET surtout en 2021 le dépôt des marques Xtra-Lucem et Lucem-Light qui caractérisent le développement de nouveau composite plus léger (-50% vs des composites ou pièces en aluminium classiques) et plus résistant (+30%)

Ces approches permettent de proposer des gammes de produit avec des masses réduites ce qui est favorable pour diminuer notre empreinte carbone, réduire les coûts de transports, ou la manutention lors du déploiement des caissons.

De nombreux rapports d'essais et de qualifications sont disponibles

BRC protège auprès de l'INPI ses modèles et ses innovations pour sécuriser ses clients.

BRC est une PMI localisée en Bretagne au plus proche des centres de développement et universitaires de la région Rennaise. BRC travaille essentiellement avec le tissu industriel local qui est varié et reconnu pour son savoir-faire ce qui permet une grande flexibilité dans la gestion des projets. Implanté dans une région dynamique BRC bénéficie des meilleures infra structures et peut gérer au mieux un personnel fidèle et compétent.

Cette stratégie de travailler français et local a particulièrement été utile pour gérer la crise COVID