Normes et essais

La société BRC est l'une des rares sociétés du marché à être EN 9100 - obligatoire pour produire pour le marché Aéronautique - Défense - Spatial.

Nous savons répondre aux exigences des :

- Normes OTAN (STANAG 4280 nato levels of packaging - STANAG 4370 environmental testing)

- Normes ISO (ISO780 emballages pour le marquage relatif à la manutention - NF L80-090 inscription d'aeronef - ISO 60529 degrés de protection codes IP)

- Normes Défense (GAM EG13 essais généraux en environnement - GAM EMB1 réalisations et contrôles des emballages - GAM EMB2 - méthod... [En savoir +]

Normes et essais

La société BRC est l'une des rares sociétés du marché à être EN 9100 - obligatoire pour produire pour le marché Aéronautique - Défense - Spatial.

Nous savons répondre aux exigences des :

- Normes OTAN (STANAG 4280 nato levels of packaging - STANAG 4370 environmental testing)

- Normes ISO (ISO780 emballages pour le marquage relatif à la manutention - NF L80-090 inscription d'aeronef - ISO 60529 degrés de protection codes IP)

- Normes Défense (GAM EG13 essais généraux en environnement - GAM EMB1 réalisations et contrôles des emballages - GAM EMB2 - méthode et réalisation de conditionnement et protection physico chimique et mécanique) - GAM EMB3 classification des matériaux - NORMDEF 0102 environnement mécanique - NORMDEF 0201 matériel défense - NORMDEF 001 couleurs ....)

- Norme ATA300, packaging of airline supply

- Norme 1-4.S - Protection des personnes et caissons de munitions

- Norme TEMPEST Level A shielding attenuation

BRC dispose également d'une bibliothèque d'essais (décompression et décompression rapide, brouillard salin - chutes - vibrations - CEM -...) pour répondre à vos questions.

Toutes ces normes/certificats et rapports sont fournis après audit ou essais réalisés par des organismes indépendants (BVT - DGA - Emitech - Apave - ...)

Une organisation industrielle adaptée au besoin d'une grande réactivité

1-Une capacité à produire à l’unité, en petite série ou en grande série (ateliers de montage spécifiques, machines de production non saturées, réseau de sous-traitants partenaire si nécessaire)

2-Un personnel spécialisé et polyvalent

3-Un process de production intégralement maîtrisé en interne ce qui assure une réactivité à tous les stades de la vie du projet

4-Une expertise dans la production de caissons en fibre de verre et résine depuis plus de 30 ans

5- Une capacité de proposer des caissons en aluminium ou de l'usinage dans la masse si nécessaire

6-Un parc de plus de 1 200 moules permettant de produire immédiatement la dimension voulue. Dans les cas exceptionnels où la dimension n'existe pas alors BRC saura réaliser le moule voulu en interne et en quelques semaines

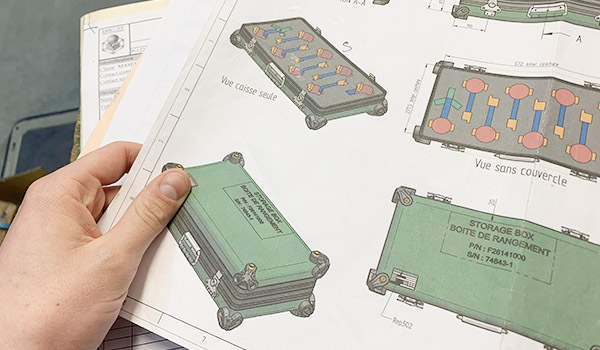

Les équipes commerciales et bureau d'étude sont en relation directe avec vos équipes achats ou techniques pour suivre l'ensemble des étapes de la vie de votre projet (de la Spécfication Techniques du Besoin à la livraison finale).

BRC travaille avec les logiciels solidedge ce qui nous permet de pouvoir intégrer directement les plans 3D de nos clients

Le fait d'avoir géré plus de 3 500 projets différents donne un savoir faire unique a notre BE pour répondre à toutes vos interrogations.

Fabrication des Moules

Cabine de Gelcoat

Étuvage

Stratification

Atelier Xtra Lucem et Lucem Light

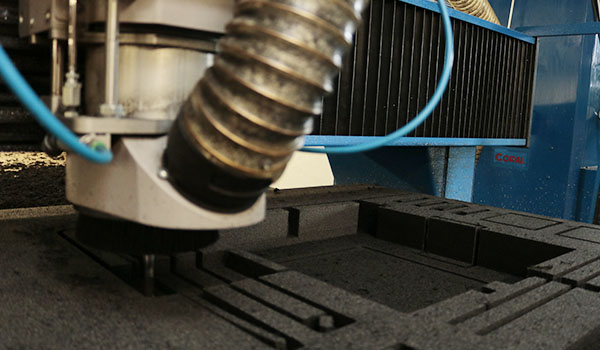

Usinage

Polissage

Profilé aluminium

Coupe

Cintrage standard ou Outlook

Soudure

Traitement et Peinture

Usinage Numérique

Poinçonnage / Pliage

Ajustage

Traitement et peinture

Usinage numérique & découpe à fil

Accastillage et gestion de la sous traitance

Assemblage mousses

Assemblage châssis aluminium ou Lucem Light

Assemblage des caissons Aluminium / Composites ou Xtra Lucem

Blindage / Noyage / Shoopage

Controle

Sous atmosphère contrôlée Sérigraphie ou marquage par transfert

Contrôle unitaire et photographie avant expédition

Élaboration des DJD / DC / Certificats matières /...

Expédition obligatoire à la palette (et non au poids) pour sécuriser les flux

Possibilite d'organiser des transports directs si nécessaire

Possibilite de mettre en place un système de tracking pour gérer le flux de transport et informer l'ensemble des acteurs des heures d'arrivée ( Géolocalisation ***)